Machine Repair Problem

| In[1]:= |  X |

| In[2]:= |  X |

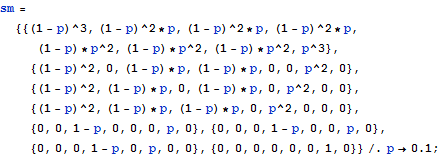

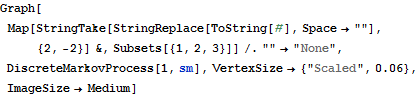

A machine shop has three machines, where on a given day a machine fails with probability  . Machine 1 feeds both machines 2 and 3, so if machine 1 fails, there is no production that day. Only one machine can be repaired on the same day so it is available for the following day. If several machines are down, they are repaired in priority order 1, 2, and 3. A machine that has been repaired is assumed to be working the next day. The states enumerate all possible combinations of failed machines, and the process starts with all machines working. Visualize the process, with the vertex labels showing the machines that are down.

. Machine 1 feeds both machines 2 and 3, so if machine 1 fails, there is no production that day. Only one machine can be repaired on the same day so it is available for the following day. If several machines are down, they are repaired in priority order 1, 2, and 3. A machine that has been repaired is assumed to be working the next day. The states enumerate all possible combinations of failed machines, and the process starts with all machines working. Visualize the process, with the vertex labels showing the machines that are down.

| Out[2]= |  |

There is production if no machines are down, or only one of machines 2 and 3 is down.

| In[3]:= | X |

| In[4]:= | X |

| Out[4]= |

| In[5]:= | X |

| Out[5]= |

The probability that there is production at full capacity.

| In[6]:= | X |

| Out[6]= |

The average time it takes to get from all machines down to no machines down.

| In[7]:= | X |

| Out[7]= |